709-218-7927 The Landfall Garden House 60 Canon Bayley Road Bonavista, Newfoundland CANADA A0C 1B0 |

|---|

Ploughing

In earlier days, farmers would park a traction engine at one end of a field, and winch a plough from the far end; shift the traction engine to the other end, plough another furrow.

Requirements

I have a 24’x16’ bed that needs to be broken up, ploughed, harrowed, scarified and so on. I have electric motors from stripped down machines such as vacuum cleaners.

There are many videos on hand-drawn cultivating, but so far they all show plowing of an already ploughed patch. I am looking to break up a 20-year old patch of lawn and turn it into a ploughed patch. I have to cope with the shallow rope-like roots of aspen trees.

Scarifying is a piece of cake compared to my task.

The main benefit of this plough is the use of electrical energy to power the ploughing. If it takes two minutes to pull the blade the length of the bed, that’s two minutes that I can use to collect litter..

A 2,500 lb trailer winch (2 speed) is $70 at Canadian Tyre . I suppose I could get greater leverage with a longer handle. One ton seems about right for cutting roots of Aspen trees. How to estimate my needs?

A 2,000 lb 12v DC electric winch from Princess Auto is $100.

The blade must be strong enough and sharp enough to cut through roots 1 cm diameter.

The blade must be able to slide over or to one side of rocks embedded in the ground.

The stone-ballast should be mobile enough to change the point of pressure on the blade. The sled load can slide.

Raking and/or sieving pebbles that sit in loosened earth is a separate task.

The concept of a multi-purpose winch suggests that I could mount the winch in the shed and pull a snow-wedge up my driveway from the street. I could use the root plough to break up the windrow built by the council.

Any form of hand-held method seems pointless. I want this machine to work for me, largely unattended. In particular I have no visual evidence of any root; I know from past experience with a shovel that they will be there.

Something like a rotary saw that would just make 6-inch deep cuts back and forth across the lawn would suit me, providing that it could slice through roots and not get upset at rocks.

Ideally a slicing blade that pauses when it meets a tree root, and a rotary or oscillating saw that can then be lowered to engage and cut the tree root.

Failing that a slicing blade that, as it begins to rise over a root, triggers a shift in loading to apply more weight (hence pressure on the blade)

The portable winch will use various blocks to resist the plough. For example, with a pile of soil against the inside of the end plank, the planks that border the bed will provide a string resistance to movement. Imagine too iron rods pounded into the ground on the immediate inside face of the planks.

Forty-six inches – just under four feet – is the gap between the outside of the bed plank and the south wall of the house. Three feet seems a safe bet for space available at any side of the bed.

Can the small (quarter-inch?) axle of the electric motor serve as a capstan to wind thicker cable onto a winch? If so I get an extra mechanical advantage.

I am focused on mains power rather than using a 12vDC winch because mains power is uninterruptible and provides a higher amperage. By that I mean that I am running a 2,500 watt baseboard heater of a 240v circuit in my house, so a 1,200 watt of 120v AC should be doable outside.

The original beds ran east-west, so these beds, embedded within the new bed, provide a testing ground for easy-work. The lawn area bordering outside the bed provide a hard-work environment. That ploughed area might then be covered in sawdust to provide a weed-free access path for barrows, ramps and so on.

The motor and winch can sit on a platform hinged at the side facing the plough. Imagine the winch established at the eastern edge, pulling the plough from the western edge. At some time the plough will baulk, because it has reached the eastern end and is blocked by the ten-inch plank, or because the blade has encountered a stubborn tree root or an embedded stone. The winch continues to wind the cable; something has to give. And it does!

Since the blade can’t move, the winch must move. The winch is on a hinged platform, so the winch begins to wind itself in an effort to climb over the ten-inch plank or die. The hinged base lifting disconnects the electrical plug and socket with provide electrical power TO the winch FROM the base plate. Neat, eh?

Acceptance

The plough must be portable (by one man with a wheel barrow) and cope with a variety of locations, at least three, in Bonavista.

At least one site should produce ploughed land at the rate of one square foot per minute. This sounds un-ambitious, but recall that a 16’ strip ploughed in 15 minutes is one square foot per minute. And yes, that fifteen minutes can be spent tossing sticks, rocks or operating an in-site percussion sieve.

Phases

Phase 001 Power supply is from a winch made of 1cm steel rod bent into the shape of a crank handle. The 1cm diameter of the rod takes up a cable. The 30cm length of the crank handle gives me a 1:30 power multiplier.

If it takes 5 minutes to pull a plough through a furrow (even a first-pass shallow furrow), then at one-foot intervals it will take 15 furrows to plough, say 75 minutes. This seems impossible, that I could plow almost 400 square feet in just over an hour.

Allow 15 minutes per furrow.

Phase 002 The plough will be made of steel, perhaps a stump-jump for the aspen tree roots; or maybe a sharp knife blade. A sled can hold it above the surface of the ground and a dagger can be mounted on a bolt-frame, that lets me set the depth of cut at the start of a job.

I should be able to drag the plough set at a 1 inch depth. Then re-bolt the dagger in its sheath and repeat the row at 2 inches; and so on.

Resetting this plough could be as simple as unhooking the cable, carting the plough back to the head of the furrow, and then unreeling the cable, re-hooking, and repeat.

The winch would need to be sturdy, heavy, and this will save shifting the winch by furrow too often.

Phase 003

The electric motor.

Phase 004

Phase 005

Measures

Electrical Energy

A simple measure is the difference in readings of my house meter over a period. The difference in readings gives a conservative value because the difference in readings includes the refrigerator in the kitchen, the baseboard heaters and so on.

Force

I can measure the “drawbar” of my winch by running a cable through a multi-pulley block. Ten strands offers a ratio of 1:10, so a simple spring scale reporting 100 lbs represents 1,000 lbs at the plough, right?

Acreage

Images

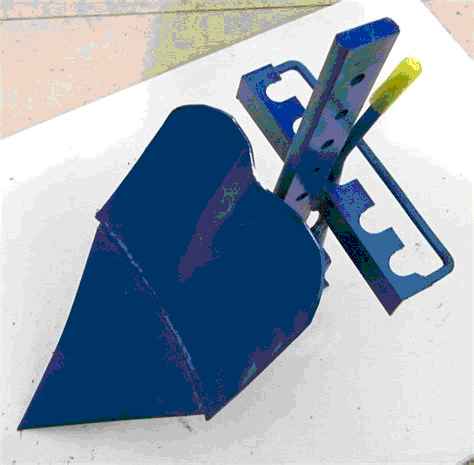

I like the appearance of these blades. They might do well at cutting through the grass roots and aspen roots, leaving the turf in vertical slices. A second cut at right-angles to the first would carve the sod into blocks, that can then be tossed and left to freeze apart over winter.

This type of blade lifts and tosses the soil. I suspect that that would need to be a separate pass for me.

I fear that this type of blade would too quickly become blunted on embedded rocks. This does not prevent me from implementing a rock-lifter, but it seems to require a means for the plough-share to jump over the rock.

Sunday, December 24, 2023

This video and this video show pulley systems. At the 1m44s mark in the second video, the presenter’s left hand identifies a five-wheel (so five-strand) system of pulleys. The right hand must travel five times the distance of the left hand, a consideration in space on the winding spindle.

More to the point, note that varying diameters of pulleys and hence the nested nature of the strands.

Note too that this example works well because the starands operate in the vertical plane. Imagine the starnds being dragged horizontally along the ground, as we might5 need for a plough.

We could devise a vertical solution with the left-hand pull being directed through ninety degrees to offer a single strand for a horizontal load.

I see that several web sites show a step-ladder supporting the vertically operating pulley system.

Tuesday, December 26, 2023

Besides a deep-cutting plough (to slice roots, loosen rocks) I need a side-throw plough as a means of heaping loose soil into a windrow. Perhaps a blade that can be used to level ouyt such a windrow. In this way I can make better use if soil and keep cleared strips to receive grass clippings during the summer?

709-218-7927 CPRGreaves@gmail.com Bonavista, Thursday, September 26, 2024 8:50 AM Copyright © 1990-2024 Chris Greaves. All Rights Reserved. |

|---|