709-218-7927 The Landfall Garden House 60 Canon Bayley Road Bonavista, Newfoundland CANADA A0C 1B0 |

|---|

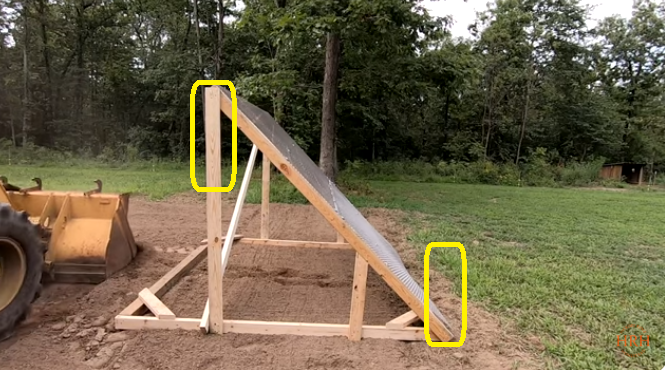

Propped Rack

A propped rack is a rack that is propped up!

This propped rack is too large for my purpose. Its job is to receive (gently!) bucket loads of rock-strewn soil. The rack is about eight feet by eight feet. The base is about the same area, the vertical frame a little less.

My propped racks will probably be my standard racks, propped up instead of being agitated on a mechanized table.

That said, if I were using a propped rack to roam around my new 24’x16’ raised bed, I would want a big enough target that I could hit without having to move the rack every few shovelfuls.

I would tack edging boards to retain the incoming hand-shovel load and prevent the load from bouncing off the screen, scattering coarse material onto a sieved bed.

Too, I might want a range of bolt holes drilled in the outlined areas so that I could raise the bottom edge high enough to receive a wheelbarrow for the coarse outflow, and so that I could (left-hand side) alter the slope of the rack to accommodate the different incoming types of material.

Remember that the dropped rack had holes drilled at each end of the frame for the handle and the axis? Those two holes could be used to receive bolts from this propping frame.

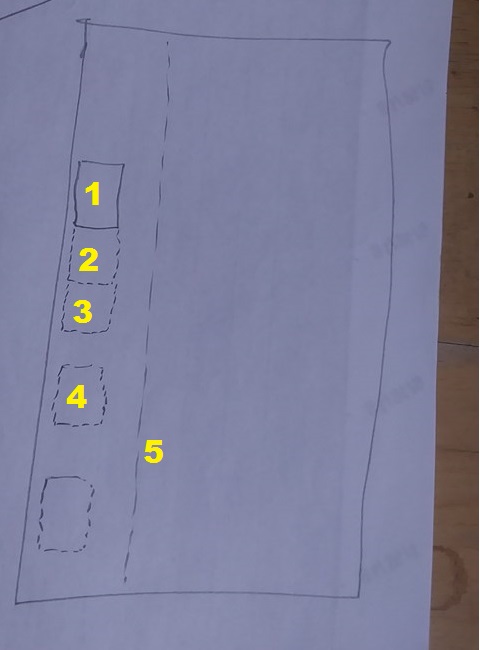

Using a Propped Rack to Roam a Garden Bed.

The large outline (6) is a garden bed.

The Propped Rack is outlined as (1), and successive positions are (2), (3) and so on. We shovel from the area just ahead of the rack, transferring the material from (2) into a sieved heap at (1). Coarse material is shoveled from the foot of (1) and carted away. Perhaps into a conveniently empty compost bin for future use in layers.

With the area (2) cleared, we drag the rack to (2) and excavate (3).

We will probably be able to excavate a larger area than just the footprint of the rack, as shown in (4). In that case the width of a strip sieved is shown by (5).

I see no harm in tossing the Coarse material to the border line (5) so that it is repeatedly sieved and we end up with a windrow at the right-hand side of the bed. That windrow can be carted away.

Three months ago I tightened nylon cords across the 24’x16’ raised bed making 24 4’x4’ partitions, mainly for illustrative purposes. I begin thinking that I should use the sixteen-square-feet partitions to process the bed, one day at a time.

(Saturday, February 24, 2024: A propped rack is lightweight and portable. We can set the rack facing backwards in its second position and dig out the first position, sifted soil falling in the second positiom. Then reverse the rack and place it in the first (emptied) position and shovel the second position onto the rack. Sifted soil falls back into the first position, usually a corner of the bed. Now the first two positions have been passed through the sieve. Advance the rack to the third position and continue working/snalking your way around/across the bed.)

Tuesday, January 23, 2024

This screen shot shows a basic propped rack with two additions

Leg extensions so that a collector bin can catch the coarse material that reaches the bottom of the sieve. I still think that a shallow angle might offer more time for material to pass through the sieve.

Two pieces of wood to funnel the coarse material into a container such as a 5-gallon pail.

As usual I note the energy required (shoveling by hand) to toss the original material to the top of the sieve. Given my comments in (1) there is reason to think that a two-foot high splash board at the head of the sieve, with the toss aimed at that headboard, might allow the entire length of the sieve to be employed.

The headboard would serve as a cheap substitute for a loading chute.

I am granting thoughts of a small conveyer belt to wander around in my head. It might be a power-take off from the primary motor. Buckets the size of corned-beef or tomato paste cans working steadily to cart material that falls from a ground-level hopper.

My particular case (composting 15 cubic yards each year) requires a supply of bacteria-laden soil as layers between the grass clippings. The coarse material could be fed directly into my compost bins.