709-218-7927 The Landfall Garden House 60 Canon Bayley Road Bonavista, Newfoundland CANADA A0C 1B0 |

|---|

Construction Methods

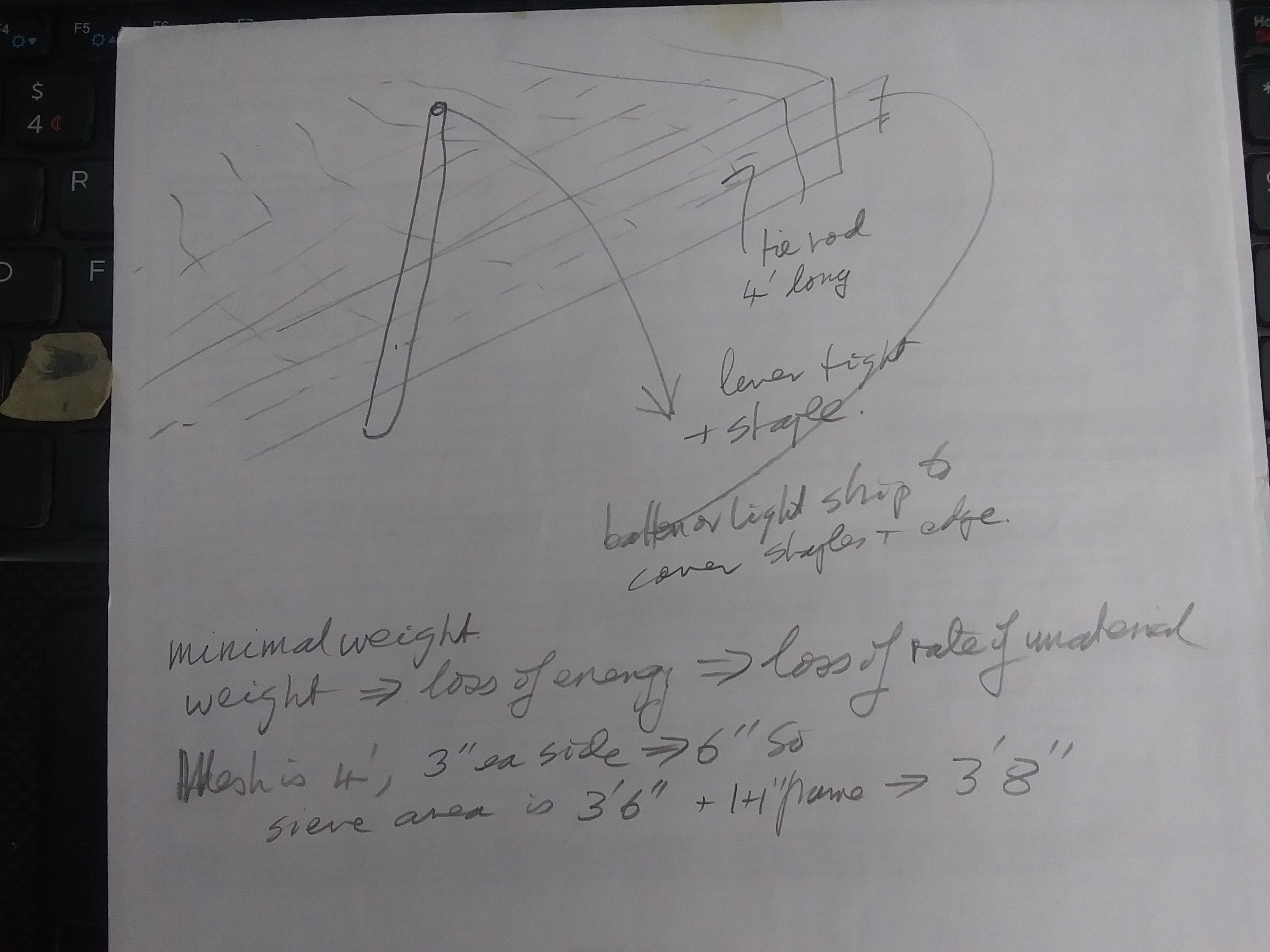

Keep in mind that I would like all sieves to be modular. To that end a Rack ought to be useable on any flat-bed sieve. Also each Rack should lightweight and stack flat for storage.

A Rack is a two-dimensional rectangular frame with a fitted mesh screen.

I fancy using cheap 2”x1” timber for the frame, with ¼” plywood for triangular braces at the corners.

The mesh used will be the coarsest available to me. Mats of finer mesh can be laid on top of the frame’s mesh.

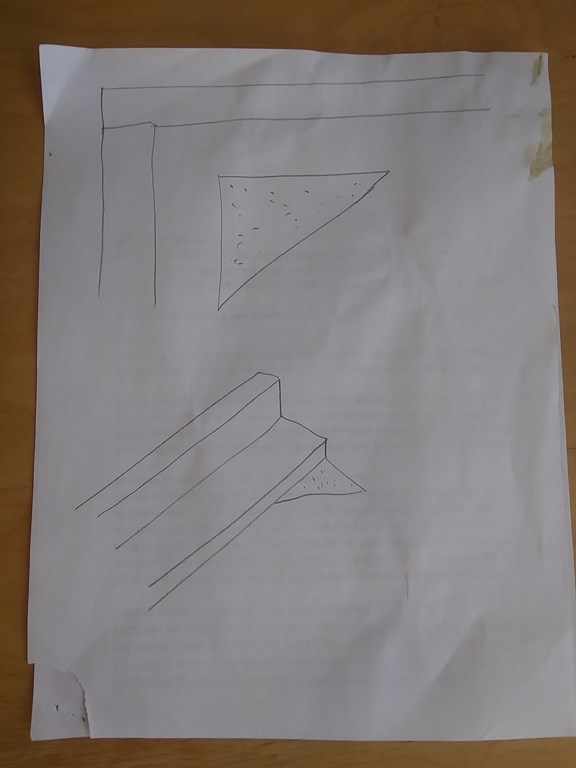

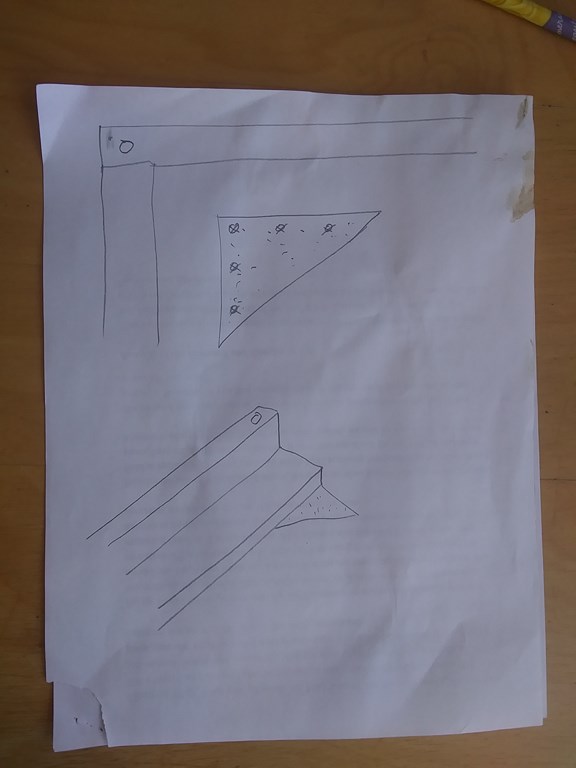

(1) A corner showing two adjoining timbers in a simple butt joint. I am not an accomplished carpenter.

The small circle was meant to represent a bolt-head, but then I remembered that I will no be dis-assembling the racks. They are rectangular frames.

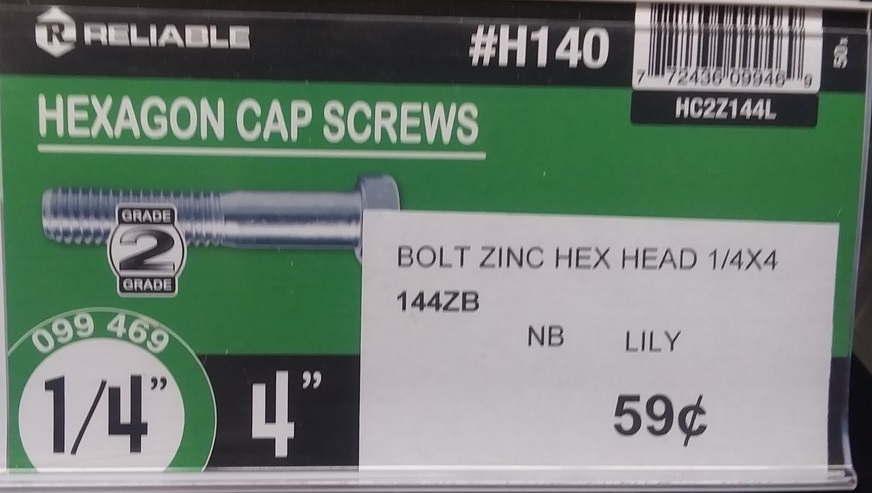

The racks will probably be bolted (not screwed) to other pieces, bolted so that they can be dis-associated from the other pieces.

A Rack is a molecuolar piece of my collection.

(2) A corner plate, with a scattering of dots representing positions for multiple screws, that will fasten the plate to the two pieces of timber that form the butt joint.

(3) A view of one of the frame pieces with a second piece mounted at right-angles.

This second piece forms a rail to inhibit scattering of material, jumping out of the rack. As well the rails hold mats in place; a mat is just a sheet of mesh with no frame.

A small piece of the triangular brace peeps out.

(4) The hole where I intended to bolt; now to be screwed.

(5) Screw holes on the plate

(6) The hole where I intended to bolt; now to be screwed.

(7) A small piece of the triangular brace peeps out.

Materials

I plan to make a new Rack next week. This frame will be built to a new (for me) standard size of 48” by 24”. This based solely on my belief that many timbers come in lengths that are multiples of 48”. I checked my stand-alone kitchen bench at 56”x24” and I think that eight square feet is a fair point between a 1.5 square foot hand sieve and a piece of farm equipment.

This first rack will be put to work as a propped rack, mounted on a simple frame whose legs, when moved, will vary the angle of attack.

The rack is symmetrical, so I will need four times the components for the segment sketched out above.

2x1 pine four feet long |

2 |

|---|---|

2x1 pine two feet long |

2 |

Triangular brace six inch sides |

1 |

4” wood screws (labeled (4) in sketch |

2 |

4” wood screws (labeled (6) in sketch |

2 |

1½” wood screws (labeled (5) in sketch |

5 |

Mesh sheet 4’x2’ |

1 |

For the rack.

2x1 pine four feet long |

2 |

8 |

16 |

|

|---|---|---|---|---|

2x1 pine two feet long |

2 |

4 |

8 |

24 feet of 2x1 pine |

Triangular brace six inch sides |

1 |

2 feet by 1 foot plywood |

||

4” wood screws (labeled (4) in sketch |

2 |

8 |

||

4” wood screws (labeled (6) in sketch |

2 |

8 |

16 4" wood screws |

|

1½” wood screws (labeled (5) in sketch |

5 |

20 |

20 1½” wood screws |

|

Mesh sheet 4’x2’ |

1 |

8 square feet mesh |

The mesh being two feet wide should fit sandwiched between the flat-laid edge and the on-edge rim. That suggests that I intend to make the wooden frame 2’x4’ exterior measurement. My sieving surface will look like 20” x 44”

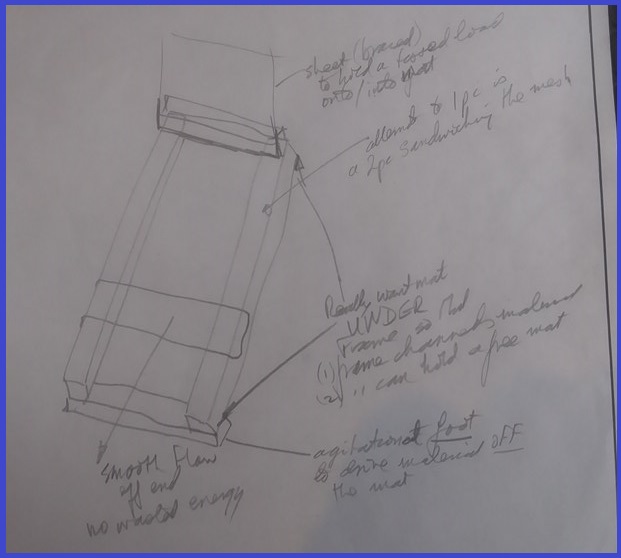

For the Propped rack, the Rack can be hinged to the Prop with drop-pin hinges.

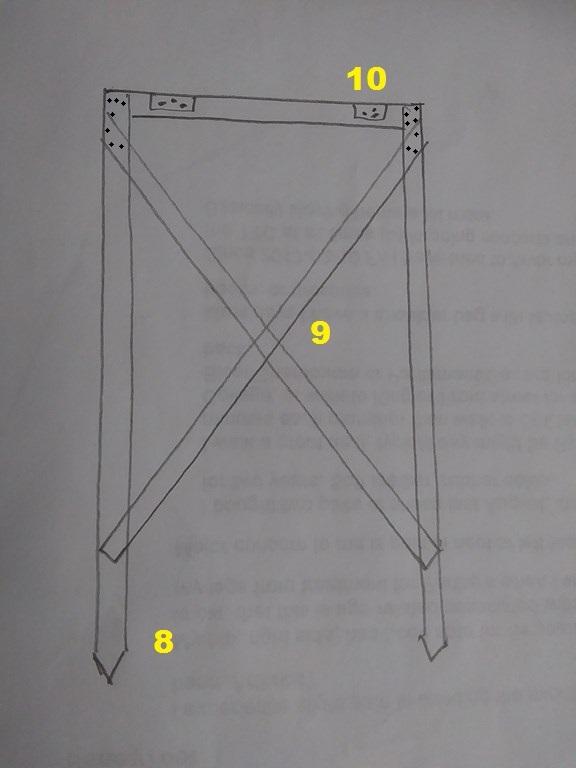

Here is a Propped panel, ready to have its two legs (8) jabbed into the ground.

Two cross-braces (9) should be enough to keep it stable.

Two drop-pin hinges (10) are screwed to the top rail.

2x1 pine four feet long |

2 |

|

|---|---|---|

2x1 pine brace four feet long |

2 |

16 feet of 2x1 pine |

Door Hinges |

2 |

2 door hinges |

1½” wood screws for hinges |

6 |

|

1½” wood screws for legs and braces |

28 |

34 1½” wood screws |

Suspension

I like the idea of suspending a rack from a frame.

Suppose racks of standard sizes (2’x4’). These racks can be placed directly on a frame that is 2’x4’.

Now suppose that we need a more complex frame. Racks suspended by cords can be suspended well within the frame – in which case the cords will be sloped towards each other – or somewhere outside the frame – in which case the cords will splay outwards.

In all cases, the rack can be vibrated horizontally, or shake upwards by a cam, or still dropped by hand. In fact in all these cases a slight log-jam in the delivery of material can probably be resolved by a manual nudge to dislodge the material that is obstructing flow, and this nudge will be accepted and absorbed by a cord suspension.\

All this while the length of the cords can be adjusted to change the angle of slope.

As well, if I find myself at the edge of the bed closest to the house wall, I can adjust the cords so that I can throw in the direction of the wall, with the rack sloped not to its long end, but to the short width facing me.

Appendix 1 – Costs

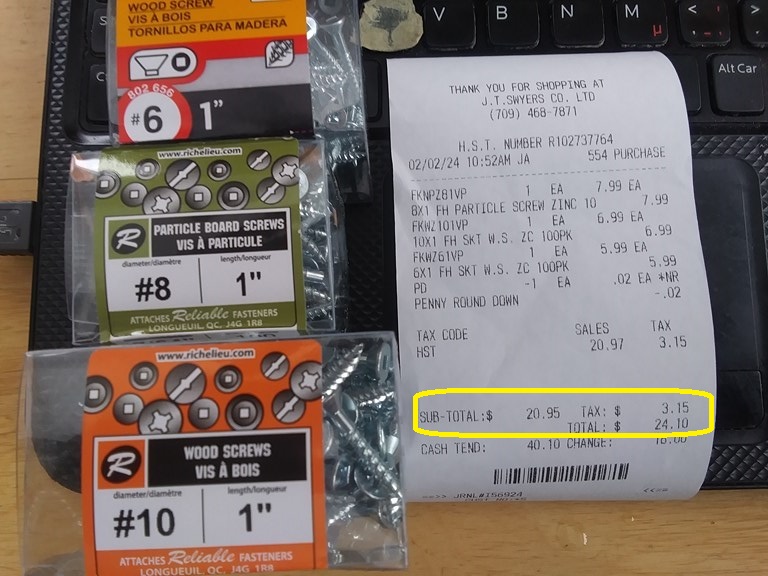

Friday, February 02, 2024 My local hardware store is at the mercy of its suppliers, and I am at the mercy of my local hardware store. That doesn’t stop me heading in there and obtaining prices.

I most commonly use one bolt, two washers, and a nut for fastening which translates to $1.34 per fastening (includes HST), but call it $1.50 where I might need a lock nut or extra washers, or even a slightly longer bolt.

I have long been puzzled by the sizing of wood screws, and since my dresser drawer of screws tumbled to the shed floor and scrambled my collections, elected to buy three packets of wood screws, 100 screws each, chamfered head, #6 and #8 and #10 to begin a new graded collection. As well I plan to have a belt across the edge of one shelf in which there is placed the tab from the box AND a sample screw. No more guessing. David tells me that the number (#8) refers to the size of the driver bit that slots into the head.

Screws come in different prices according to supplier and size, but reckon on $8.00 per hundred (includes HST).

Now I can estimate construction costs (in fasteners) for racks and sieves.

Consider a rectangular rack using one-inch screws, three at each corner, non-lapped joints. Four joints and three screws is twelve screws, so 96¢ or $1.00 per frame.

Monday, February 12, 2024

I think about racks in greater detail as the days go by.

I believe that mesh comes in four-foot wide rolls.

Wednesday, February 14, 2024

I think of a rack as four pieces of 2”x1” fastened at each corner with a traiangular braces of thin plywood. The cross-piece at one end lies atop the mesh, at the other end below the mesh.

The bottom end of the rack allows coarse material (sticks, rocks, clumps to slide off the end quickly. We do not want a cross-piece blocking the exit, because we have put our energy into tossing a shovelful of material onto the sieve, and we want to send up the next shovelful as quickly as possible.

I think of agitation being at the bottom of the rack for the same reason – we want to maximize the exit of coarse material.

We want the mesh to be fitted so as to leave a wooden raised side; it will be this wooden raised side that holds a free-floating mat of finer mesh in lace.

I can conceieve a rack made of a double layer of 2x1 with the mesh anchored or sandwiched between the two wood layers. This provides better tension on the mesh.

This is what I want for my base platform, rack or trommel. I knew this as “pig fencing” as a teenager; if a pig can’t get through it, it is strong, sturdy, and can carry a load.

Now imagine a wooden frame 8’x2’ with an 8’x2’ strip of this mesh. Useless for sieving soil.

But now cut a 4’x2’ strip of ¼-inch mesh and lay that as a mat atop the pig-pen material. Now we have a ¼-inch rack. Too fine? Peel off the ¼” mesh and toss a 1” mesh atop. Simple, fast.

Now imagine a 26” bicycle-wheel trommel with the pig-pen as the structure of the barrel. Slide in a sleeve about 24” diameter of ¼-inch mesh and we have a ¼” trommel.

“TREE ISLAND 6" x 6" 10 Gauge Construction Mesh - 4' x 7' 0 Reviews Item: #2730-403 Model: #80-0 367 269” If I understand this we have six-inch gaps in the mesh, and a 6-inch square of #10 gauge wire should be enough to support a much finer mesh.

It comes in 4’x7’ sheets. The sheets are unlikely to be bordered with #10-gauge steel, so I should allow for wastage.

The rim measurement is 72 inches, six feet, so a 7’ sheet will cover four feet of a trommel drum.. Three rims make for a four-foot long trommel, probably long enough for my rate of loading. One sheet should provide one four-foot cylinder.

Thursday, February 15, 2024

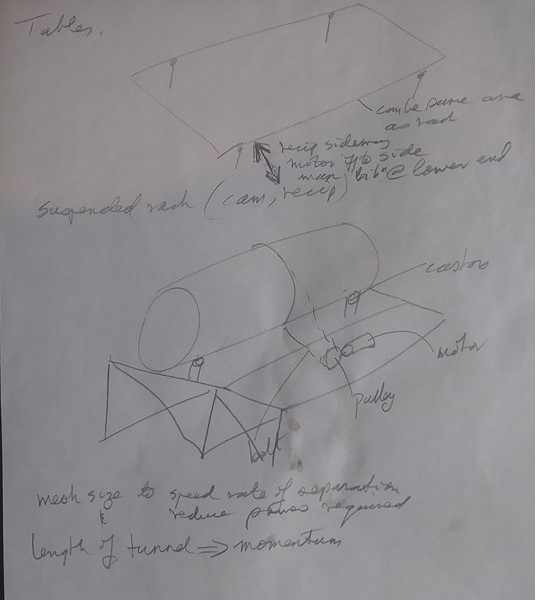

Bearing in mind that I would like the sieves and trommels to be consistent and stowable, I start by thinking that all tables should be the same size (length, width, and height).

For one thing we want to slide a wheel barrow under the centre ppart and off the end of the rack or trommel. For another thing we would like to be able to hook almost any kind of sieve or trommel to any table and send it off to work.

(1) When the table top is the same width as the racks, they stack together.

(2) Rope/cord suspension from hooks makes for easy (dis)assembly.

(3) Vibration can be lengthwise or lateral.

(4) A trommel belted drive off a centre rim might be best mounted in a shielded area off to one side. This may suggest a curved cylindrical shield around the mesh cylinder.

(5) A longer cylinder means more momentum; our mesh cylinder becomes a flywheel, but we could as easily add strips of lead inside each rim.

(6) We want a mesh size to offer the speediest rate of separation. Rolling material for a long period means we are basically chewing up energy.

Saturday, February 17, 2024

Christopher Greaves Sieves.xls

Racks

Tables

My kitchen bench is 56 inches long, 24 wide, and stands 36 inches high. It is niot sturdy enough for a vibrating rack or a rotating trommel, but is is a template for a sieve table.

See also ProppedRack\TheFirstRack.doc