709-218-7927 The Landfall Garden House 60 Canon Bayley Road Bonavista, Newfoundland CANADA A0C 1B0 |

|---|

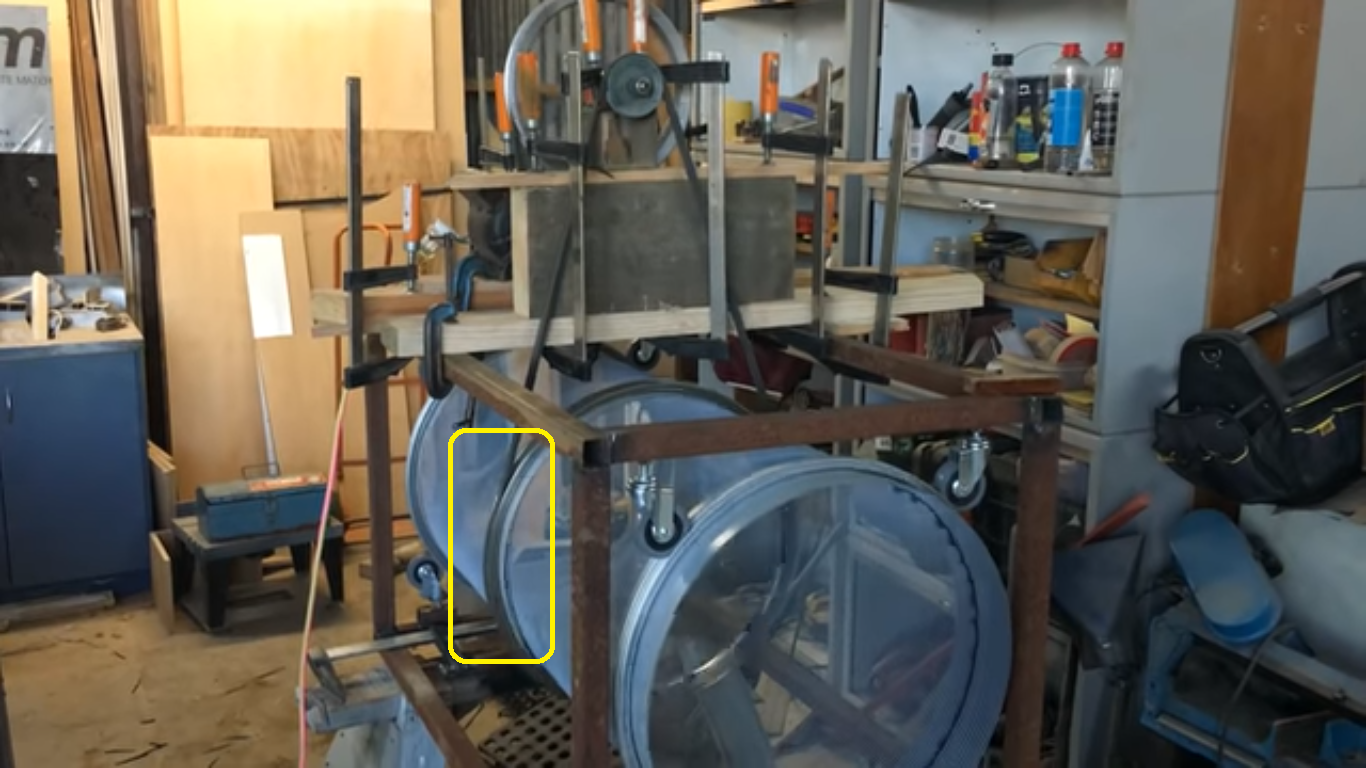

Belt-Driven Trommel

The belt-driven trommel is driven by a flexible belt or cord.

The belt must pass over a pulley of some sort fixed to the axle of the trommel, and that means an axle, and that suggests welding, as well as an obstruction to the open cylinder of mesh.

Or the belt can be passed around the outside of the mesh cylinder itself, if the cylinder is strong enough. Which it probably will not, given that its being assaulted by shovelfuls of soil and rock and wet grass clippings.

I would like to try a set of wooden laths running the length of the cylinder and strapped to the outside of the mesh. These laths will obstruct passage of fine material to the outside world, but if I have a large enough number of laths, the stress from the belt should be borne by the laths and transmitted directly to the rims.

A belt drive directly to the rims presents two problems:-

(1) How do we avoid conflict with the castors?

(2) If we drive a rim at the end of the cylinder, a turning force will be applied and the cylinder might quickly crumple into a spiral

I considered briefly a chain and sprocket drive; after all, some bicycle wheels have sprockets. Multi-gear sprockets too, which would be attractive in terms of a variety of loads and/or operating speeds.

Friday, January 19, 2024

Screw a three-inch steel flashing at each bicycle wheel rim to sandwich the mesh and prevent grit from entering the rim/belt space.

[Over]Lapped mesh does not hurt the operation at all. “Better a three-inch lap that a one-inch gap”

Large wheel to produce a wheel-barrow device.

A simple platform to mount a motor above a Sieve.

Saturday, February 03, 2024

This video shows a top-mounted motor.

(1) The trommel is driven by belt on the central of three bicycle rims; this spreads the load or torque, which seems to me to be a good thing.

(2) I have doubts about trommels that produce fine clay-like soil. I suspect (but do not know) that without twigs, shards of rock and so on, this sieved soil will compact and provide no tunneling for drainage or worm avenues.

(3) I have NO experience in operating rotary trommels, but in general they seem to be rotating too quickly, tossing the material onto the mesh, rather than sliding material along the mesh. If this trammel’s gearing were reduced another 1:3 then the motor would be delivering more torque-per-pound mass and the “ride” might be smoother.